ONLY was part of the Dish Mob Braga event 23rd edition, “Industry 4.0 – From theory to reality”, held in Portugal on May 12th, 2017. Among the public were public authorities, academics and industry representatives.

António Ferreira, head of R&D at Enancer Electronics, described a practical case related to the theme: The use of new materials, namely additive and subtractive materials, the manipulation of productive processes using advanced robots and the ease of connecting Smart Factories with Design and prototyping software, which open up new opportunities for the production of small series and customization.

Enancer is providing an example of how industrial customization opens up opportunities for differentiation and affirmation in niche markets with greater value proposition. It is an SME from Braga, majority owned by Fehst Componentes, a car parts manufacturer. The company develops, produces and markets products under the ONLY Smart Home brand, offering a comprehensive home automation solution for homes and hotels.

They are genuine “Made in Portugal” products, conceived and designed to be different from competition not only in functionality, but above all, in the simplicity of use, installation and configuration.

Rather than adopting a standard communication protocol, the company developed a proprietary protocol that opens up wider possibilities for differentiation at the solution level.

In terms of industrial customization during hardware manufacturing, the variety of electronic boards was minimized by designing them to be common to several modules easily reconfigurable in the productive process either at the hardware level – addition/removal of functions – Firmware to be embedded. In addition to flexibility, this has led to cost reductions – less dispersion of stocks, scalability of production, etc.

Regarding the housing of the modules and their visual aspect, through shared synergies with Fehst Componentes and its competence and experience in components manufacturing for the automotive sector, ONLY became more competitive through the “customization offer”.

The built-in wall mount modules share the same plastic housing. Polymeric and pigment additives attribute properties such as flame retarding, colouring options, etc., to the modules.

Regarding human interface devices, the company works on materials with anti-bacterial properties, as well as UV-curable paint finish to provide greater mechanical durability and chemical resistance.

Increasingly, people value possessing something that has been specially made for them, which may even be the “deciding factor” during the purchase journey. A few examples that can be given:

- At Hotel Meliã in Braga the room switches have colours and symbols designed by the architect himself. On the same day of the production panels of the standard line were also made.

- In the Ideia-Atlântico building in in Braga, the wireless switches are glued to the dividing glass walls. The challenge in this case was the reconfiguration of existing HW.

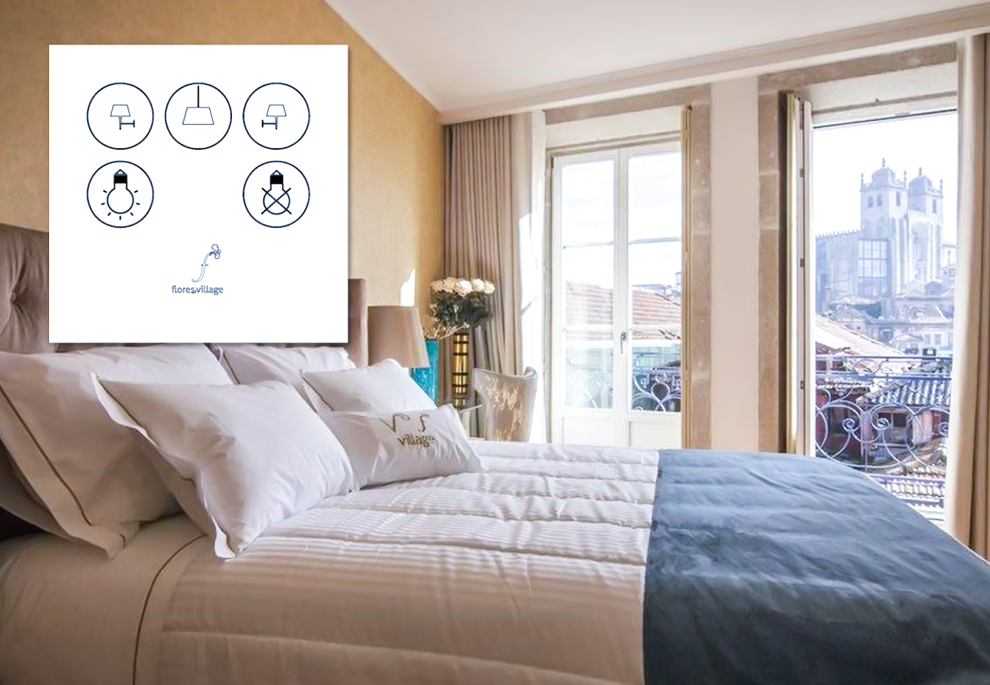

- In the rooms of the award-winning Hotel Flores in Porto, a personalized set of symbols switches was made for the switches (see illustration).

- A family home near Baden-Baden in Germany has the colour, symbols and logo that the architect carefully planned and designed. As soon as the CAD drawings were received, they were prepared and transferred to the recording equipment for execution.

- In a house in Pune in India, there was a late decision to change the finishing of the touch panels from matte to high-gloss. The batch that was already in preparation was easily reconverted.

Nowadays the timeframe from decision, choices and date of delivery is crucial. It has to be shorter and shorter! People see, like, and want immediately. They do not expect you to say “now you have to wait a few weeks until delivery”. If there is delay, enthusiasm fades!

All of this has only been and is increasingly possible because the design and manufacturing processes are increasingly automated and interconnected with exchange and transfer of data.

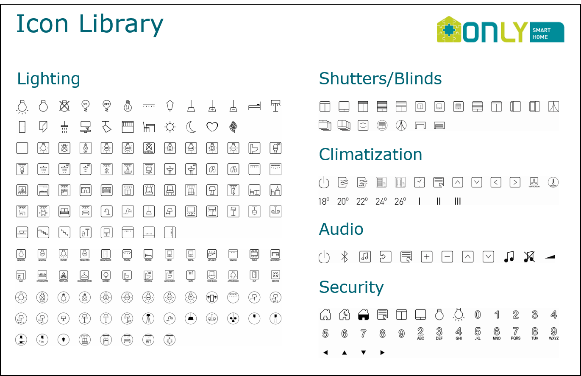

Example symbol library that can be applied to the panels.